Home > Company Introduction

Company Overview

Su\'an Intelligent is a high-tech R&D and manufacturing enterprise specializing in animal identification, traceability, and smart farming solutions. By integrating IoT, AI, big data, and wireless communication technologies, we provide one-stop solutions for: Livestock Management: Real-time monitoring & smart farming systems. Animal Traceability: Reliable tracking from farm to market. Livestock Finance/Insurance: Data-driven risk assessment & digital asset services.

-

ManufacturerBusiness Type

-

2015Year Established

-

YesOverseas Office

-

1,000-3,000 square metersFactory Size

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

51 - 100 People Total Employees

-

1-10 People Sales Staff

-

5-10 People Quality Inspectors

-

ISO9000 Product Certifications

-

Below US$1 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

Shenzhen Port of Shipment

-

Yes Overseas Office

-

Ear Tag Main Industry

-

Quality ControlQuality Assurance Our company has established a comprehensive quality management system standard. Every process—from raw material intake, secondary processing, secondary injection molding, chip coding, to laser engraving—undergoes rigorous inspection to ensure 100% product yield. Additionally, our dedicated quality control department conducts random inspections at each process stage to monitor compliance A well-established production system A.Incoming Material Quality Inspection Procedure B.Process Quality Verification Procedure C. Shipping Inspection Procedure D、Nonconforming Product Handling A. Functional defects; B. Over-assembly, under-assembly, or missing components; C. Incorrect packaging methods, mixed shipments, or erroneous labeling; D. Product dimensional nonconformity; E. Product fabrication deviating from drawing specifications; F. Incorrect material specifications; G. Incorrect coding, garbled characters, etc.; H. Same cosmetic defect occurring three consecutive times within one week on identical products

Quality ControlQuality Assurance Our company has established a comprehensive quality management system standard. Every process—from raw material intake, secondary processing, secondary injection molding, chip coding, to laser engraving—undergoes rigorous inspection to ensure 100% product yield. Additionally, our dedicated quality control department conducts random inspections at each process stage to monitor compliance A well-established production system A.Incoming Material Quality Inspection Procedure B.Process Quality Verification Procedure C. Shipping Inspection Procedure D、Nonconforming Product Handling A. Functional defects; B. Over-assembly, under-assembly, or missing components; C. Incorrect packaging methods, mixed shipments, or erroneous labeling; D. Product dimensional nonconformity; E. Product fabrication deviating from drawing specifications; F. Incorrect material specifications; G. Incorrect coding, garbled characters, etc.; H. Same cosmetic defect occurring three consecutive times within one week on identical products -

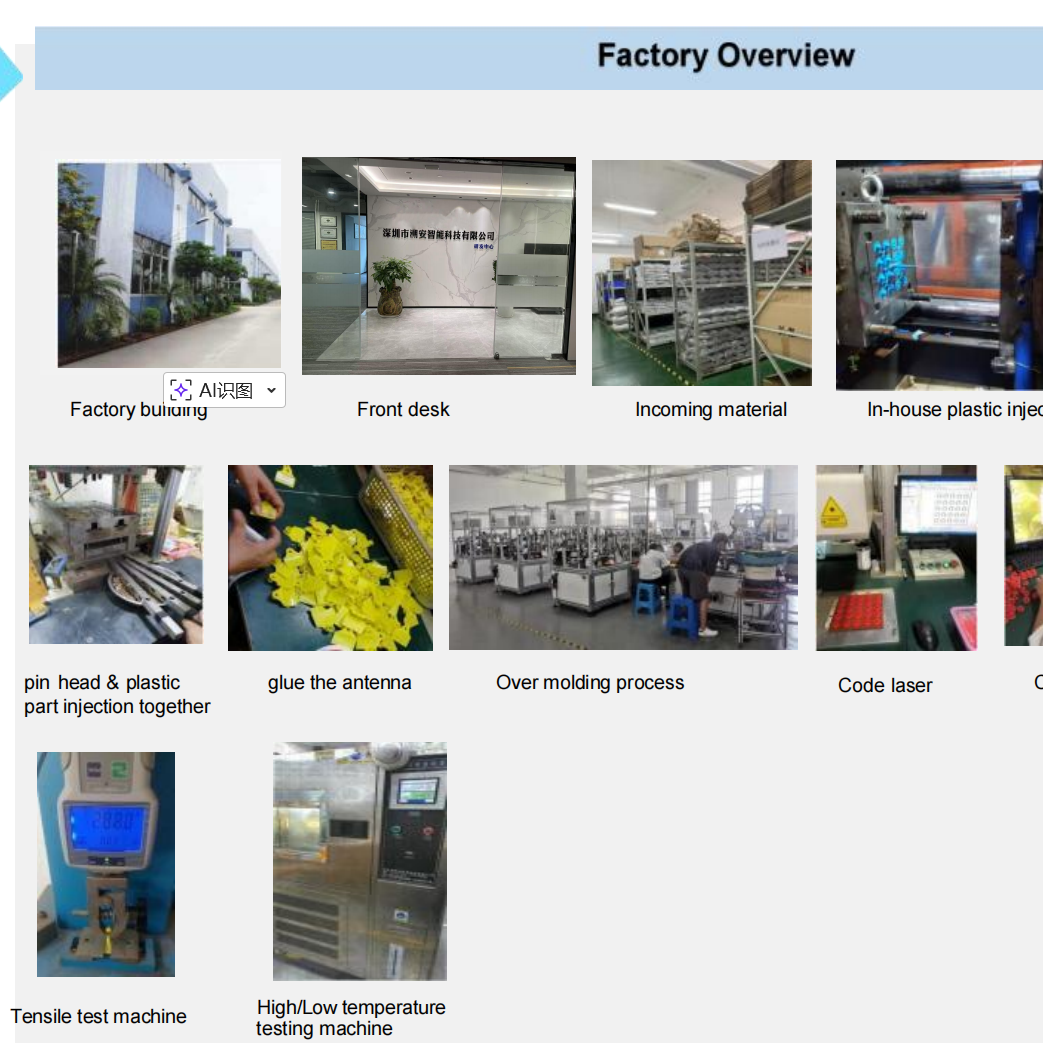

Our ServicesProduct Manufacturing Our company independently developed and deployed a Manufacturing Execution System (MES) at our factory. This system is a production information management solution designed for the shop floor execution layer of manufacturing enterprises. It tracks and records the production transformation process from raw materials to finished goods. 1. A stable technical team and production workforce. 80% of our technical backbone has worked for over five years, with production staff consistently maintained at around 70 employees. 3. Production bottleneck tracking: Our after-sales service specialists coordinate production and shipping schedules with clients. Adjustments are confirmed within 30 minutes to guarantee timely and accurate deliveries. 4. Rapid Production Capacity: Our company possesses over 90 sets of UHF and LF electronic ear tag molds for pigs, cattle, and sheep, as well as plastic ear tag molds.

Our ServicesProduct Manufacturing Our company independently developed and deployed a Manufacturing Execution System (MES) at our factory. This system is a production information management solution designed for the shop floor execution layer of manufacturing enterprises. It tracks and records the production transformation process from raw materials to finished goods. 1. A stable technical team and production workforce. 80% of our technical backbone has worked for over five years, with production staff consistently maintained at around 70 employees. 3. Production bottleneck tracking: Our after-sales service specialists coordinate production and shipping schedules with clients. Adjustments are confirmed within 30 minutes to guarantee timely and accurate deliveries. 4. Rapid Production Capacity: Our company possesses over 90 sets of UHF and LF electronic ear tag molds for pigs, cattle, and sheep, as well as plastic ear tag molds. -

Company HistoryEstablished in year 2015, which is a professional RFID manufacture specializes in animal ID products, including electronic animal ear tag, Smart livestock ear tag,implantable Animal microchip, RFID readers and software solutions etc. We have full in-house ID/MD/Electronics / software engineers who have over 10 years experience in RFID application, so that we can tailor the products based on your rough concept or requirements. Meanwhile, we offer competitive price and follow strict quality controlling, and our products have exported to many overseas countries, meeting with the standard of ISO11784/11785 etc. Just contact us now for your new OEM/ODM orders.

Company HistoryEstablished in year 2015, which is a professional RFID manufacture specializes in animal ID products, including electronic animal ear tag, Smart livestock ear tag,implantable Animal microchip, RFID readers and software solutions etc. We have full in-house ID/MD/Electronics / software engineers who have over 10 years experience in RFID application, so that we can tailor the products based on your rough concept or requirements. Meanwhile, we offer competitive price and follow strict quality controlling, and our products have exported to many overseas countries, meeting with the standard of ISO11784/11785 etc. Just contact us now for your new OEM/ODM orders. -

Our TeamWe have produced over 50 million electronic ear tags, accumulating extensive experience in engineering cases, process technology, product testing, and workflow management. 2. Ample production equipment utilizing advanced processes and machinery, such as high-tonnage injection molding machines and high-power laser marking machines, enhances production efficiency. Our facilities include 16 high-tonnage injection molding machines, 12 high-power laser marking machines, and 15 coding devices. We can deploy up to 5 sets of molds based on order requirements to ensure a daily production capacity exceeding 60,000 sets.

Our TeamWe have produced over 50 million electronic ear tags, accumulating extensive experience in engineering cases, process technology, product testing, and workflow management. 2. Ample production equipment utilizing advanced processes and machinery, such as high-tonnage injection molding machines and high-power laser marking machines, enhances production efficiency. Our facilities include 16 high-tonnage injection molding machines, 12 high-power laser marking machines, and 15 coding devices. We can deploy up to 5 sets of molds based on order requirements to ensure a daily production capacity exceeding 60,000 sets.

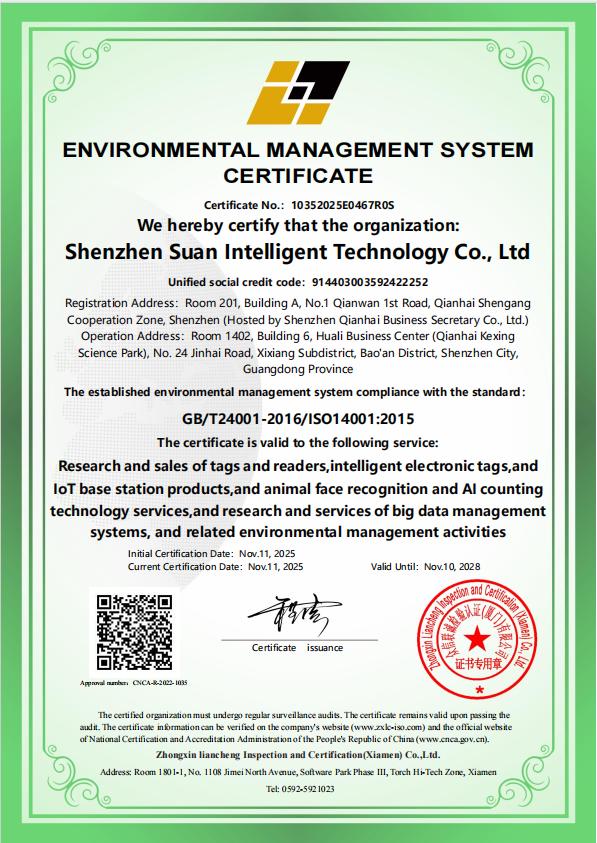

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.